Page 642 - Lewis

P. 642

West System Epoxy 641

Special Clear Hardeners

No. 207 Special Coating Hardener No. 209 Extra-Slow Hardener

FIG 5522b

207 Special Coating Hardener is formulated for use with WEST

SYSTEM Brand 105 Resin in coating applications where an FIG 5523b

extremely clear finish is desired, especially when working in

humid and/or low-temperature conditions. Also provides ade- 209 Extra-Slow Hardener is formulated for use with WEST

quate adhesion for bonding applications. Contains a UV-stabi- SYSTEM Brand 105 Resin in extremely warm and/or humid

lization additive. Increases the longevity of oil and conditions for general bonding and coating applications, pro-

polyurethane varnishes. Provides 20-25 minutes of pot life at viding approximately twice the pot life and working time as

72°F (22°C), and will cure to a solid state in 9 to 12 hours. 206 Slow Hardener. 209 Extra Slow Hardener will provide ade-

Minimum recommended temperature is 60°F (16°C). quate pot life up to 110°F (43° C). May also be used in normal

Maximum strength occurs over the next 4 to 7 days. Use #300 temperatures — 65°F (18°C) to 72°F (22°C) — when additional

pump set to achieve the proper 3 parts 105 Resin to 1 part 207 pot life and assembly time may be desirable. Provides 15 to 20

Hardener mixture. May also be dispensed with 306-3 high minutes of pot life at 95°F (35°C) and 40 to 50 minutes at 72°F

capacity pumps. (22°C). Will cure to a solid state in 6 to 8 hours at 95°F and in

USE WITH SPECIAL RATIO DISPENSING PUMP 20 to 24 hours at 72°F. Maximum strength occurs over the next

No. Each Size Ratio Case 4 to 9 days. Forms a clear, amber-colored solid. The 309-3 dis-

207SA $44.40 .66 pts. 3:1 4 penses up to 5 quarts per minute and its reservoirs hold 2 gal-

207SB 99.80 .33 gal. 3:1 4 lons of resin and 1 gallon of hardener. Not recommended for

207SC 323.00 1.45 gal. 3:1 1 clear coating.

WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov USE WITH SPECIAL RATIO DISPENSING PUMP

No. Each Size Ratio Case

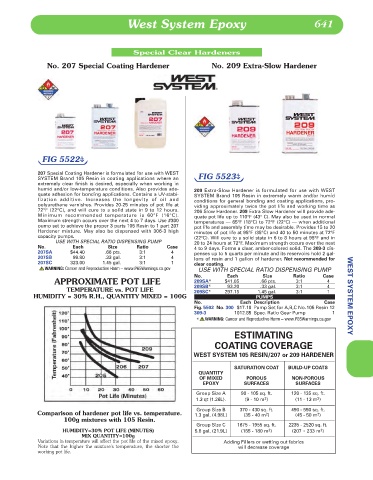

APPROXIMATE POT LIFE 209SA* $41.05 .66 pts. 3:1 4

209SB* 93.20 .33 gal. 3:1 4

TEMPERATURE vs. POT LIFE 209SC* 297.15 1.45 gal. 3:1 1

HUMIDITY = 30% R.H., QUANTITY MIXED = 100G PUMPS WEST SYSTEM EPOXY

No. Each Description Case

Fig. 5502 No. 300 $17.10 Pump Set for A,B,C No.105 Resin 12

309-3 1012.85 Spec. Ratio Gear Pump 1

* WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov

ESTIMATING

COATING COVERAGE

WEST SYSTEM 105 RESIN/207 or 209 HARDENER

SATURATION COAT BUILD-UP COATS

QUANTITY

OF MIXED POROUS NON-POROUS

EPOXY SURFACES SURFACES

Group Size A 90 - 105 sq. ft. 120 - 135 sq. ft.

1.3 qt (1.26L). (9 - 10 m 2 ) (11 - 13 m 2 )

Group Size B 370 - 430 sq. ft. 490 - 550 sq. ft.

Comparison of hardener pot life vs. temperature. 1.3 gal. (4.98L) (35 - 40 m 2 ) (45 - 50 m 2 )

100g mixtures with 105 Resin.

Group Size C 1675 - 1955 sq. ft. 2235 - 2520 sq. ft.

HUMIDITY=30% POT LIFE (MINUTES) 5.8 gal. (21.9L) (155 - 180 m 2 ) (207 - 233 m 2 )

MIX QUANTITY=100g

Variations in temperature will affect the pot life of the mixed epoxy. Adding Fillers or wetting out fabrics

Note that the higher the mixture's temperature, the shorter the will decrease coverage

working pot life.