Page 6 - Perko

P. 6

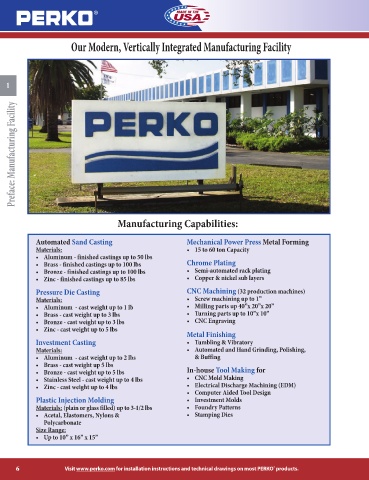

Our Modern, Vertically Integrated Manufacturing Facility

1

Preface: Manufacturing Facility

Manufacturing Capabilities:

Automated Sand Casting Mechanical Power Press Metal Forming

Materials: • 15 to 60 ton Capacity

• Aluminum - finished castings up to 50 lbs

• Brass - finished castings up to 100 lbs Chrome Plating

• Bronze - finished castings up to 100 lbs • Semi-automated rack plating

• Zinc - finished castings up to 85 lbs • Copper & nickel sub layers

Pressure Die Casting CNC Machining (32 production machines)

Materials: • Screw machining up to 1”

• Aluminum - cast weight up to 1 lb • Milling parts up 40”x 20”x 20”

• Brass - cast weight up to 3 lbs • Turning parts up to 10”x 10”

• Bronze - cast weight up to 3 lbs • CNC Engraving

• Zinc - cast weight up to 5 lbs

Metal Finishing

Investment Casting • Tumbling & Vibratory

Materials: • Automated and Hand Grinding, Polishing,

• Aluminum - cast weight up to 2 lbs & Buffing

• Brass - cast weight up 5 lbs

• Bronze - cast weight up to 5 lbs In-house Tool Making for

• Stainless Steel - cast weight up to 4 lbs • CNC Mold Making

• Zinc - cast weight up to 4 lbs • Electrical Discharge Machining (EDM)

• Computer Aided Tool Design

Plastic Injection Molding • Investment Molds

Materials: (plain or glass filled) up to 3-1/2 lbs • Foundry Patterns

• Acetal, Elastomers, Nylons & • Stamping Dies

Polycarbonate

Size Range:

• Up to 10” x 16” x 15”

6 Visit www.perko.com for installation instructions and technical drawings on most PERKO products.

®