Page 238 - Vetus

P. 238

HOW TO DETERMINE THE CORRECT VETUS STEERING

Various combinations of boat speed, rudder blade surface area and balance sections apply a variety of forces on steering systems.

Furthermore the dynamic influences of wind and currents cause steering systems to be continuously used under sometimes harsh

conditions.

A skipper is dependent on the steering system and therefore it must be reliable under all circumstances. The design of the steering

system determines how rapidly the vessel responds to helm movements. Fast light vessels react quickly to small rudder movements,

while a slow, heavy displacement vessel will usually be set up to require more wheel movement for a given change of course.

A thoughtful calculation of a steering system is therefore essential.

This chapter explains how the appropriate steering system can

be determined for any boat.

Make your choice from a wide range of steering wheels and

steering systems in this chapter.

RUDDER TORQUE

The choice of the correct cylinder is determined by the rudder torque in Nm (or kg). The rudder torque is the determining factor

(Torque = force x lever). To ascertain the correct rudder torque, only the maximum speed of the vessel, the surface area of the

rudder blade and the maximum rudder angle (in degrees) are of importance. Information such as length of boat and engine power

are irrelevant. With a few exceptions, the rudder performs best with a maximum rudder angle of 35º to either side. Contrary

to what is sometimes claimed for rudders with normal dimensions, a larger rudder angle does not enhance the manoeuvring

capabilities of a vessel.

Your VETUS customer support representative will be pleased to provide you with recommendations for all steering system

components, based on the maximum speed of the vessel and a dimensioned sketch or the rudder (provided by you).

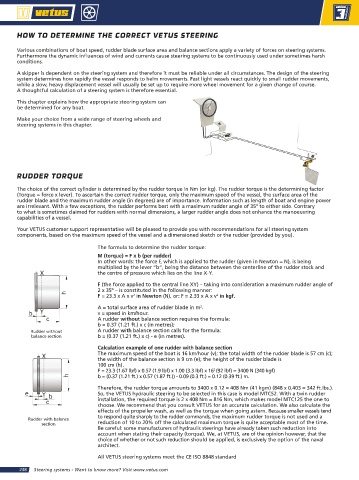

The formula to determine the rudder torque:

M (torque) = F x b (per rudder)

In other words: the force F, which is applied to the rudder (given in Newton = N), is being

multiplied by the lever ”b”, being the distance between the centerline of the rudder stock and

the centre of pressure which lies on the line X-Y.

F (the force applied to the central line XY) – taking into consideration a maximum rudder angle of

2 x 35º – is constituted in the following manner:

F = 23.3 x A x v in Newton (N), or: F = 2.33 x A x v in kgf.

2

2

A = total surface area of rudder blade in m .

2

v = speed in km/hour.

A rudder without balance section requires the formula:

b = 0.37 (1.21 ft.) x c (in metres);

Rudder without A rudder with balance section calls for the formula:

balance section b = (0.37 (1.21 ft.) x c) - e (in metres).

Calculation example of one rudder with balance section

The maximum speed of the boat is 16 km/hour (v); the total width of the rudder blade is 57 cm (c);

the width of the balance section is 9 cm (e); the height of the rudder blade is

100 cm (h).

2

F = 23.3 (1.67 lbf) x 0.57 (1.9 lbf) x 1.00 (3.3 lbf) x 16 (92 lbf) = 3400 N (340 kgf)

b = (0.37 (1.21 ft.) x 0.57 (1.87 ft.)) - 0.09 (0.3 ft.) = 0.12 (0.39 ft.) m.

Therefore, the rudder torque amounts to 3400 x 0.12 = 408 Nm (41 kgm) (848 x 0.403 = 342 ft.lbs.).

So, the VETUS hydraulic steering to be selected in this case is model MTC52. With a twin rudder

installation, the required torque is 2 x 408 Nm = 816 Nm, which makes model MTC125 the one to

choose. We recommend that you consult VETUS for an accurate calculation. We also calculate the

effects of the propeller wash, as well as the torque when going astern. Because smaller vessels tend

to respond quite sharply to the rudder commands, the maximum rudder torque is not used and a

Rudder with balance

section reduction of 10 to 20% off the calculated maximum torque is quite acceptable most of the time.

Be careful: some manufacturers of hydraulic steerings have already taken such reduction into

account when stating their capacity (torque). We, at VETUS, are of the opinion however, that the

choice of whether or not such reduction should be applied, is exclusively the option of the naval

architect.

All VETUS steering systems meet the CE ISO 8848 standard

238 Steering systems - Want to know more? Visit www.vetus.com