Page 609 - Lewis

P. 609

608 Alexseal Yacht Coatings

®

®

WHILE

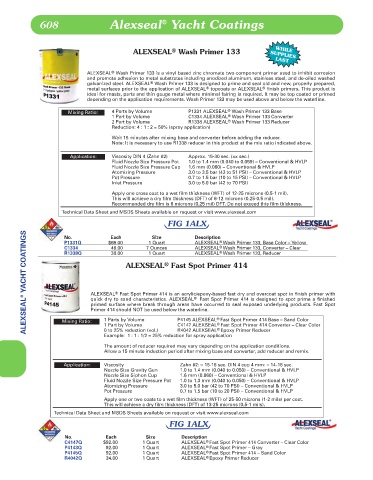

ALEXSEAL Wash Primer 133 SUPPLIES

LAST

ALEXSEAL ® Wash Primer 133 is a vinyl based zinc chromate two-component primer used to inhibit corrosion

and promote adhesion to metal substrates including anodized aluminum, stainless steel, and de-oiled washed

galvanized steel. ALEXSEAL ® Wash Primer 133 is designed to prime and seal old and new, properly prepared,

metal surfaces prior to the application of ALEXSEAL ® topcoats or ALEXSEAL ® finish primers. This product is

ideal for masts, parts and thin gauge metal where minimal fairing is required. It may be top coated or primed

depending on the application requirements. Wash Primer 133 may be used above and below the waterline.

Mixing Ratio: 4 Parts by Volume P1331 ALEXSEAL ® Wash Primer 133 Base

1 Part by Volume C1334 ALEXSEAL ® Wash Primer 133 Converter

2 Part by Volume R1338 ALEXSEAL ® Wash Primer 133 Reducer

Reduction: 4 : 1 : 2 = 50% (spray application)

Wait 15 minutes after mixing base and converter before adding the reducer.

Note: It is necessary to use R1338 reducer in this product at the mix ratio indicated above.

Application: Viscosity DIN 4 (Zahn #2) Approx. 15-30 sec. (xx sec.)

Fluid Nozzle Size Pressure Pot 1.0 to 1.4 mm (0.040 to 0.059) – Conventional & HVLP

Fluid Nozzle Size Pressure Cup 1.6 mm (0.060) – Conventional & HVLP

Atomizing Pressure 3.0 to 3.5 bar (43 to 51 PSI) – Conventional & HVLP

Pot Pressure 0.7 to 1.5 bar (10 to 15 PSI) – Conventional & HVLP

Inlet Pressure 3.0 to 5.0 bar (42 to 70 PSI)

Apply one cross coat to a wet film thickness (WFT) of 12-25 microns (0.5-1 mil).

This will achieve a dry film thickness (DFT) of 6-12 microns (0.25-0.5 mil).

Recommended dry film is 6 microns (0.25 mil) DFT. Do not exceed this film thickness.

Technical Data Sheet and MSDS Sheets available on request or visit www.alexseal.com

FIG 1ALX

YACHT COATINGS P1331Q $69.00 ALEXSEAL Fast Spot Primer 414

Size

No.

Each

Description

ALEXSEAL ® Wash Primer 133, Base Color – Yellow

1 Quart

7 Ounces

46.00

ALEXSEAL ® Wash Primer 133, Converter – Clear

C1334

38.00

ALEXSEAL ® Wash Primer 133, Reducer

R1338Q

1 Quart

®

ALEXSEAL ® Mixing Ratio: ALEXSEAL ® Fast Spot Primer 414 is an acrylic/epoxy-based fast dry and overcoat spot in finish primer with

quick dry to sand characteristics. ALEXSEAL ® Fast Spot Primer 414 is designed to spot prime a finished

primed surface where break through areas have occurred to seal exposed underlying products. Fast Spot

Primer 414 should NOT be used below the waterline.

1 Parts by Volume

P4145 ALEXSEAL ® Fast Spot Primer 414 Base – Sand Color

1 Part by Volume

C4147 ALEXSEAL ® Fast Spot Primer 414 Converter – Clear Color

0 to 25% reduction (vol.)

R4042 ALEXSEAL ® Epoxy Primer Reducer

Example: 1 : 1 : 1/2 = 25% reduction for spray application

The amount of reducer required may vary depending on the application conditions.

Allow a 15 minute induction period after mixing base and converter, add reducer and remix.

Application: Viscosity Zahn #2: ≈ 15-18 sec. DIN 4 cup 4 mm: = 14-18 sec.

Nozzle Size Gravity Gun 1.0 to 1.4 mm (0.040 to 0.050) – Conventional & HVLP

Nozzle Size Siphon Cup 1.6 mm (0.060) – Conventional & HVLP

Fluid Nozzle Size Pressure Pot 1.0 to 1.3 mm (0.040 to 0.050) – Conventional & HVLP

Atomizing Pressure 3.0 to 5.0 bar (42 to 70 PSI) – Conventional & HVLP

Pot Pressure 0.7 to 1.5 bar (10 to 20 PSI) – Conventional & HVLP

Apply one or two coats to a wet film thickness (WFT) of 25-50 microns (1-2 mils) per coat.

This will achieve a dry film thickness (DFT) of 13-25 microns (0.5-1 mils).

Technical Data Sheet and MSDS Sheets available on request or visit www.alexseal.com

FIG 1ALX

No. Each Size Description

C4147Q $92.00 1 Quart ALEXSEAL ® Fast Spot Primer 414 Converter – Clear Color

P4143Q 92.00 1 Quart ALEXSEAL ® Fast Spot Primer – Gray

P4145Q 92.00 1 Quart ALEXSEAL ® Fast Spot Primer 414 – Sand Color

R4042Q 34.00 1 Quart ALEXSEAL ® Epoxy Primer Reducer