Page 745 - Lewis

P. 745

744 Exhaust System

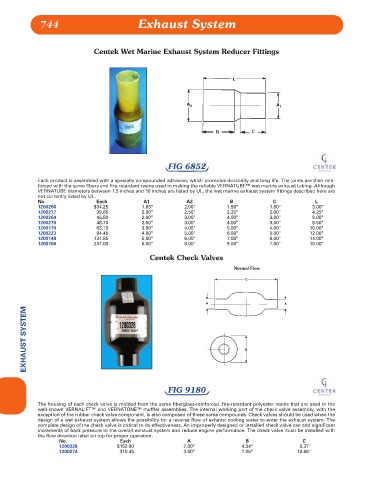

Centek Wet Marine Exhaust System Reducer Fittings

B C

FIG 6852

Each product is assembled with a specially compounded adhesive, which promotes durability and long life. The joints are then rein-

forced with the same fibers and fire-retardant resins used in making the reliable VERNATUBE™ wet marine exhaust tubing. Although

VERNATUBE diameters between 1.5 inches and 10 inches are listed by UL, the wet marine exhaust system fittings described here are

not currently listed by UL.

No. Each A1 A2 B C L

1200266 $34.25 1.63" 2.00" 1.50" 1.50" 3.00"

1200277 39.65 2.00" 2.50" 2.25" 2.00" 4.25"

1200264 45.80 2.00" 3.00" 4.00" 3.00" 8.00"

1200270 48.70 2.50" 3.00" 4.00" 3.50" 8.50"

1200170 63.10 3.00" 4.00" 5.00" 4.00" 10.00"

1200223 94.45 4.00" 5.00" 6.00" 5.00" 12.00"

1200148 134.85 5.00" 6.00" 7.00" 6.00" 14.00"

1200166 247.00 6.00" 8.00" 9.00" 7.00" 18.00"

Centek Check Valves

Normal Flow

EXHAUST SYSTEM

FIG 9180

The housing of each check valve is molded from the same fiberglass-reinforced, fire-retardant polyester resins that are used in the

well-known VERNALIFT™ and VERNATONE™ muffler assemblies. The internal working part of the check valve assembly, with the

exception of the rubber check valve component, is also composed of these same compounds. Check valves should be used when the

design of a wet exhaust system allows the possibility for a reverse flow of exhaust cooling water to enter the exhaust system. The

complete design of the check valve is critical to its effectiveness. An improperly designed or installed check valve can add significant

increments of back pressure to the overall exhaust system and reduce engine performance. The check valve must be installed with

the flow direction label on top for proper operation.

No. Each A B C

1200328 $152.90 2.00" 4.34" 8.37"

1200274 310.45 3.00" 7.06" 18.66"